Geschichte

When you get to hear the „Rennsteiglied“ . . .

... in the beautiful Thuringian Forest, you will find the idyllic climatic spa Kleinschmalkalden. For more than 200 years the old craft of cow bell production has been practised here.

Due to the high rainfalls on the slopes of the Thuringian Forest and the lush mountain meadows, there has always been a lively grazing which resulted in a high demand of cow bells.

Already in 1874 Friedrich Venter, great-great-grandfather of the present managers Bärbel Hartig and David Venter, has founded the company for productin of grazing bells, smiths Venter.

By now, our company is family-run by the 5th generation and family-owned for more than 140 years. The founder Johann Friedrich Venter (1850-1904) was followed by the owners Karl August Venter (1881-1963) and Friedrich Venter (1911-1998). During the GDR the company was forced into expropriation and had to continue as VEB Kunstgewerbe Pappenheim, the management always remained in the hands of the family. In 1990, the company was re-privatized and recalled to Venter-Glocken GmbH, managed by Hubert Venter until 2005. Since 2005, Bärbel Hartig and David Venter have been managing the business together.

Chronological

History

1874 · Foundation of the company Thüringer Kuhglockenfabrik by Johann Friedrich Venter

1905 · Continuation of the business by August Venter

1937 · Deletion of Register of Craftsmen and Registration on the Chamber of Commerce in Gotha. Changing from the Register of Craftsmen to the Chamber of Commerce the company became industrial.

01.01.1951 · Friedrich Venter took over the company from his father August Venter.

08.08.1959 · the companies Friedrich Venter and Horst Schorcht merged into „PGH Venter-Glocken“.

1963 - 1972 · Hubert Venter became regional manager in the division I (parent company)

17.04.1972 · „PGH Venter-Glocken“ was changed into VEB Kunstgewerbe Pappenheim“ and Hubert Venter was appointed as manager.

01.06.1990 · Foundation of the company „Venter-Glocken GmbH“ by Reprivatisation. The shareholders voted for the director Hubert Venter.

08.08.2003 · Ceremonial induction of the biggest cowbell of the world „Größte Kuhglocke der Welt“ (the production time was about one year)

01.05.2005 · Since May 2005 Bärbel Hartig and David Venter are managing the company

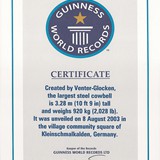

Biggest Cowbell of the world

Guinness World Records - 2003

Our company even got an entry in the book of Guinness World Records. The biggest cowbell of the world was ceremonially inaugurated on 8th August 2003 on the occasion of the 625th anniversary of Kleinschmalkalden. The production took about one year and it is located near the company building, on the main street in the village.

Technical Information

| Height of the bell (incl. gallow) | 3,28 Meter |

| Height of the bell (without gallow) | 3,10 Meter |

| Ellipse bottom border | 2,00 x 1,60 Meter |

| Length of the bell clapper | 2,43 Meter |

| Total weight of the bell | 920 kg |

| Bell clapper | 25 kg |

| Gallow | 80 kg |

| Material of the bell | 5 mm sheet steel |

| Material of the Gallow | 60 mm round steel |

| Material of the clapper stack | 35 mm round steel |

| Material of the clapper poppet | 95 mm round steel |

The entire surface refinement was done by the company Witte GmbH. |

|

| a) | Surface work by sanblasting |

| b) | Zinc was sprayed on the whole bell to avoid rusting |

| c) | Priming of the bell |

| d) | Levelling out of uneven surfaces |

| e) | Topcoating with textured paint for metal |

The bell coating consists of 12 parts, the upper part is manufactured in 25 units. The final painting was done by Hans-Joachim Münch. The biggest cowbell of the world was ceremonially inaugurated on 8th August 2003 on the occasion of the 625th anniversary of Kleinschmalkalden. The production took about one year On 14th August 2011 the bell was moved in a pageant to its present location.

Looking into the future

Continuation and Development

In the next years we would like to continue with our craft tradition, of course, and constantly develop our production and distribution. We would be pleased to welcome you as a new customer having a heart for tradition and German craftsmanship. Please visit us at our webshop here on our website.

Webshop

Order online

In our webshop you can buy many different bells such souvenirs, table bells, herd bells, music bells, sport-/fan bells and ship’s bells.

Visit our Webshop